Differences between drill and screwdriver

Clearly, however, the difference between a drill and a screwdriver goes far beyond this, since these tools, evolving on different levels, are able to obtain different results and in some cases overlap.

They can perform similar tasks but this does not mean that you can give up certain features. Here, then, is some insight into what these power tools are, how to use them and when it is best to work with one or the other. Or you can decide to use one of the two indiscriminately.

INDEX

1. Use and characteristics of the drill

A drill is a cordless or corded tool that allows you to insert a threaded bit into a chuck. Once tightened, this bit can do its job, which can be drilling, countersinking, turning, or milling. Much depends on the shape you choose.

Some bits allow the drill to transform into a milling machine or a lathe, although not quite with the features of a dedicated tool. However, in most cases the difference between a drill and a screwdriver is that the drill is dedicated to drilling work. So you can make holes in concrete, metal, wood.

Above all, you can do this with precision and professionalism. If you need to drill wood without burrs, you need to use a drill that can reach certain parameters in terms of speed and stability of work. With the right tip and a sufficiently powerful drill, perhaps a hammer drill, you can drill practically anything.

The drill is therefore distinguished by its having a chuck in which the bits are inserted and fixed. Sometimes the drills are equipped with an additional handle and a depth rod.

In a drill you usually have the possibility of adjusting the maximum number of revolutions and you have the possibility during the working phase of accelerating or slowing down the spindle speed up to the maximum speed.

The drill is also often equipped with a hammer mechanism. Hammer action is a mechanism that moves the drill bit back and forth, striking and crushing the hardest material. It is measured in blows per minute. Powerful models can exceed 50,000 blows per minute, but for occasional work a model with around 20,000 blows per minute is sufficient. To understand how hammer action works, imagine someone banging the back of the drill while you are drilling, this is why a hammer drill can feel like a jackhammer in your hands. Some cordless drills are equipped with a hammer mechanism, with a lower hammer rate than corded drills.

2. What is a screwdriver used for?

Its main purpose is to rotate an insert to communicate a clockwise and anticlockwise rotary movement that is used, precisely, to screw or unscrew. Generally it allows the use of inserts in the shape of a cross-head and flat screwdriver, but also with a hexagonal and tube tip to intervene on bolts and pins.

One of the main features that distinguishes it from the drill is the tightening torque. The tightening torque is the force that the screwdriver is able to impart to the rotation, generally much higher than that of a drill that does not need to impart much force in the rotary movement. The tightening torque is measured in Newtons per meter (Nm). The higher this value is, the more the device is able to screw screws in very hard materials or to tighten or unscrew large bolts.

In order to obtain greater tightening torque, screwdrivers are generally equipped with an impact mechanism. Unlike the hammer mechanism in drills which strikes perpendicular to the hole, the impulse mechanism strikes in the direction of rotation and thus increases its force.

The screwdriver does not have a chuck but a connection that can only be hexagonal, for screw inserts, or square for socket wrenches.

The screwdriver also has a reversible function. Reversibility allows you to rotate the insert in both directions, simply by moving the appropriate lever. This function allows you to screw and unscrew.

The main advantage of an electric screwdriver is that it is easy to use since you can work on a large number of screws in minimal time. If your job is very long, you can speed up the work substantially.

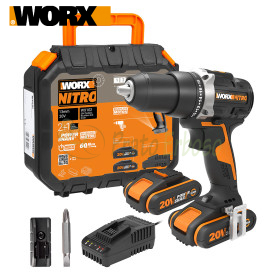

3. The drill driver is the middle way

The drill driver can do the work of drilling as well as screwing and unscrewing. It is a power tool halfway between a drill and a screwdriver both aesthetically and functionally.

These models have a speed regulator and in some cases also the possibility of switching to percussion for drilling building materials.

In addition, at least the more advanced models have a torque regulator, perfect for tightening a screw as a torque wrench would, and a reversibility button that allows you to vary the direction of rotation to allow for screwing and unscrewing.

The drill driver has more torque than a drill but not as much as a screwdriver since they do not have an impact mechanism.

4. Which one to choose?

There is no certain and definitive answer.

The drill is always the ideal tool for drilling any surface that you may encounter in everyday life. However, it is better to choose one with a percussion movement in order to have a greater possibility of intervention.

The screwdriver may seem like an unnecessary tool if you are used to screwing and unscrewing with manual tools, but after trying it you realize that it can be really practical especially if you are often engaged in assembly and disassembly work.

A good tool that can drill and screw can be useful to avoid having to constantly change tools. But it is clear that if you have to work on very hard materials, a large number of times in a short time, having specific tools and therefore drills designed only for drilling makes the difference.

The same is true among screwdrivers. For every job there is a tool. The only way to sleep soundly is to have a well-equipped workshop with the right tool for every occasion.

Share this content

Related products