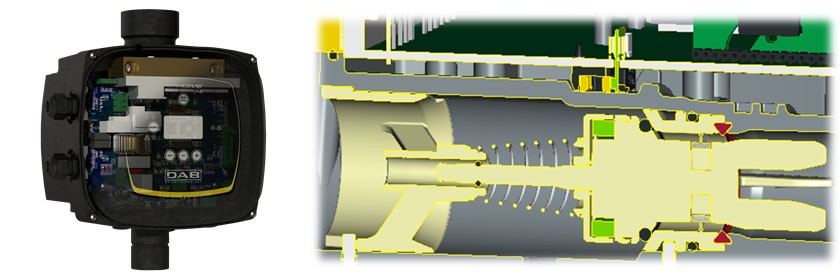

Active Driver Plus M/T 2.2 - 10.5 A single-phase/three-phase inverter

For three-phase pumps up to 3 HP. Single-phase/three-phase.

Delivery Options

| Carrier | Description | Estimated Delivery | |

|---|---|---|---|

| Mail Boxes - 2 giorni | This courier delivers within 48 hours from the moment we entrust the products to him. | Monday 9 March - Tuesday 10 March |

| Poste Italiane - 2 giorni Italia | This courier delivers within 24/48 hours from the moment we entrust them with the products. | Monday 9 March - Tuesday 10 March |

| DHL - 2 giorni Italia | This courier delivers within 24/48 hours from the moment we entrust the products to him. | Monday 9 March - Tuesday 10 March |

| Poste Italiane - 3 giorni punto di ritiro | This courier delivers within 24/72 hours from the moment we entrust them with the products. | Friday 6 March |

| Ritiro in negozio | Choose where to collect your order within 24/48 hours. | Friday 6 March |

Carrier: Mail Boxes - 2 giorni

Description: This courier delivers within 48 hours from the moment we entrust the products to him.

Estimated delivery:

Monday 9 March - Tuesday 10 March

Carrier: Poste Italiane - 2 giorni Italia

Description: This courier delivers within 24/48 hours from the moment we entrust them with the products.

Estimated delivery:

Monday 9 March - Tuesday 10 March

Carrier: DHL - 2 giorni Italia

Description: This courier delivers within 24/48 hours from the moment we entrust the products to him.

Estimated delivery:

Monday 9 March - Tuesday 10 March

Carrier: Poste Italiane - 3 giorni punto di ritiro

Description: This courier delivers within 24/72 hours from the moment we entrust them with the products.

Estimated delivery:

Friday 6 March

Carrier: Ritiro in negozio

Description: Choose where to collect your order within 24/48 hours.

Estimated delivery:

Friday 6 March

The DAB Active Driver Plus M/T 2.2 inverter finds its natural application in constant pressure pumping systems in the domestic, industrial and agricultural sectors.

It keeps pressure constant by controlling the pump speed and keeping it running at minimum speed. This reduces energy and water consumption and protects the system. When installed in a group, the second and third pumps start in cascade when the first pump reaches maximum rotation speed.

The pumps are automatically stopped in the event of overcurrent, dry running, low supply voltage, or exceeding a maximum pressure value.

The pressure can be adjusted by the user via two buttons + and -.

Innovative thanks to its dual processor technology and extremely compact, Active Driver Plus M/T 2.2 ensures new ease of installation thanks to the simple wizard.

- Power (HP)

- 3

- Suction mouth

- 1" 1/4

- Delivery mouth

- 1" 1/2

- Degree of protection

- IP 55

- Max. flow rate (l./min.)

- 300

- Max. working pressure (bar)

- Output Voltage (Volts)

- Max. liquid temperature (°C)

- Line power supply

- single-phase

- Supply voltage (Volts)

- 230

- Engine power supply

- three-phase

- Motor voltage

- 230 V

- Motor Phase Current (Amperes)

- Overcurrent protection

- Yes

- Amperometric protection

- Yes

- Short circuit protection

- Yes

- Dry running protection

- Yes

- Height (cm)

- 28.2

- Width (cm)

- 23.7

- Depth (cm)

- 18.4

- Weight (Kg)

- Warranty (years)

- 2

- Motor phase frequency (Hz)

- 50, 60

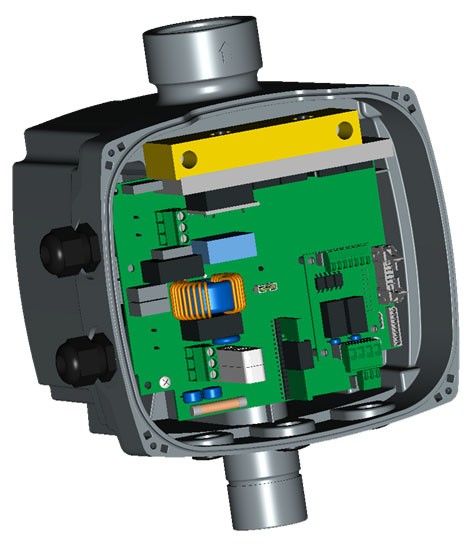

Inverter

The Active Driver Plus makes the pump absorb the minimum power necessary to meet the water needs, avoiding unnecessary waste and allowing significant energy savings.

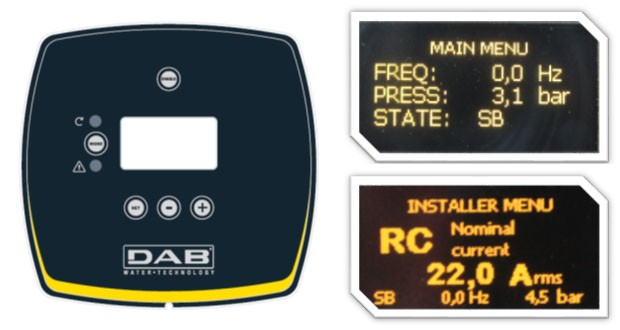

Display

Highly legible OLED display. The intuitive interface allows you to access all the information and customize the main settings according to the specification.

Increased pump life.

Thanks to the inverter technology, which reduces the motor speed, there is a considerable increase in the life of the pump.

Arrangement for operation in groups

The Active Driver Plus is designed for operation in pressurization groups. Each pump requires an Active Driver Plus that controls it in order to minimize electricity consumption.

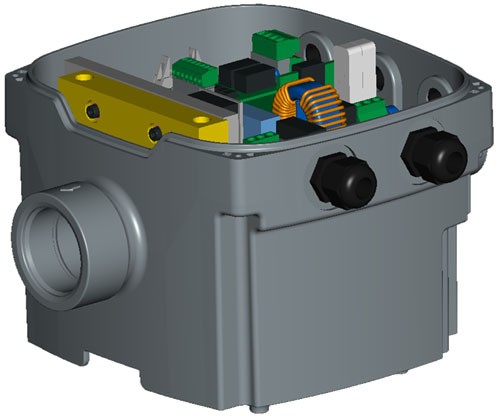

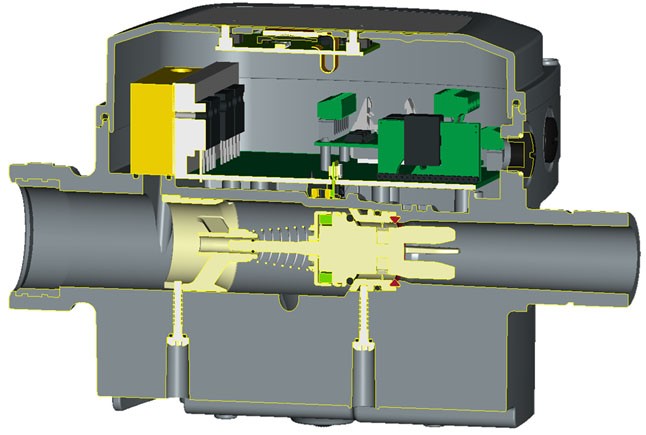

Flow and pressure sensors

Integrated electronic pressure transducer and flow sensor. The Active Driver Plus does not require external sensors.

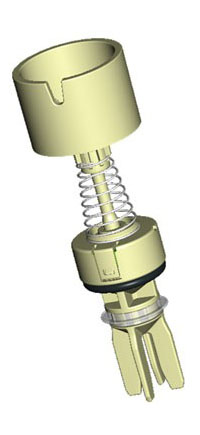

Non-return valve

Easily removable for maintenance.

MAIN DIFFERENCES WITH THE PREVIOUS MODEL |

PREVIOUS MODEL NEW PLUS MODEL |

Reliable | All the experience DAB in mechatronics has been condensed into this product which has been made extremely reliable, powerful and versatile. |

Easy to install | All the experience DAB in mechatronics has been condensed into this product which has been made extremely reliable, powerful and versatile. |

Easy to set up | The inverter, through the wizard (easily readable on the display), guides the installer to enter all the necessary parameters and in some cases helps in defining the appropriate setting. |

| |

NEW DISPLY AND SOFTWARE INTERFACE | |

SoftwareSame functionality as the previous version.Connectivity with other devices on all models up to 8 pumps.Backward compatibility of software capable of updating previous versions.OLED displaySimplified and guided installation through Wizard.Improved the usability of information thanks to the graphic display.Better visibility for high resolution and contrast.Graphic and descriptive explanation of the parameter.Possibility to choose the language of the menus.InterfaceNew 'ENABLE' key to stop / restart the machine. |

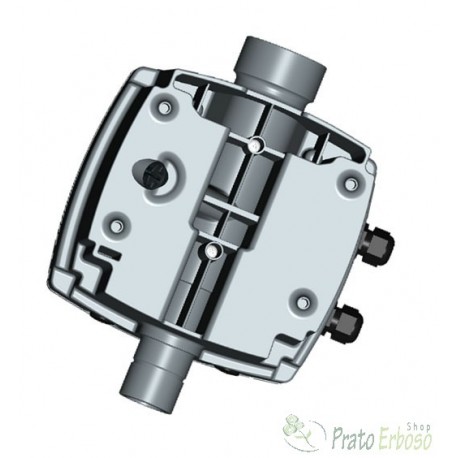

NEW CONSTRUCTION OF THE COVER | |||

| |||

NEW CONSTRUCTION OF THE BODY | |

3/8 inch plastic drain plug instead of 1/4 inch hex brass.  Extremely robust pressure sensor seat. |

NEW CONSTRUCTION OF THE SINK | |

|

NEW CONSTRUCTION OF THE ELECTRONIC BOARD | |

|

MANUFACTURING NEWS OF THE NON-RETURN VALVE | |

|

Compare with Similar Products

Active Driver Plus M/T 2.2 - 10.5 A single-phase/three-phase inverterThis product For three-phase pumps up to 3 HP. Single-phase/three-phase. |  STEADYPRES MT 10 - 10.5 A single-phase/three-phase inverterFor three-phase pumps up to 3 HP. Single-phase/three-phase. |  PWM II 230 D/10.5 - 10.5 A single-phase/three-phase inverterFor three-phase pumps up to 3 HP. Single-phase/three-phase. | |

|---|---|---|---|

| Price | Price €774.70 | Price €803.98 -42% €466.31 | Price €774.70 |

| Power (HP) | Power (HP) 3 | Power (HP) 3 | Power (HP) 3 |

| Suction mouth | Suction mouth 1" 1/4 | Suction mouth 1" | Suction mouth 1" 1/4 |

| Delivery mouth | Delivery mouth 1" 1/2 | Delivery mouth 1" | Delivery mouth 1" 1/2 |

| Degree of protection | Degree of protection IP 55 | Degree of protection IP 55 | Degree of protection IP 55 |

| Max. flow rate (l./min.) | Max. flow rate (l./min.) 300 | Max. flow rate (l./min.) -- | Max. flow rate (l./min.) 300 |

| Max. working pressure (bar) | Max. working pressure (bar) -- | Max. working pressure (bar) -- | Max. working pressure (bar) -- |

| Output Voltage (Volts) | Output Voltage (Volts) -- | Output Voltage (Volts) -- | Output Voltage (Volts) -- |

| Max. liquid temperature (°C) | Max. liquid temperature (°C) -- | Max. liquid temperature (°C) -- | Max. liquid temperature (°C) -- |

| Line power supply | Line power supply single-phase | Line power supply single-phase | Line power supply single-phase |

| Supply voltage (Volts) | Supply voltage (Volts) 230 | Supply voltage (Volts) 230 | Supply voltage (Volts) 230 |

| Engine power supply | Engine power supply three-phase | Engine power supply three-phase | Engine power supply three-phase |

| Motor voltage | Motor voltage 230 V | Motor voltage 230 V | Motor voltage 230 V |

| Motor Phase Current (Amperes) | Motor Phase Current (Amperes) -- | Motor Phase Current (Amperes) 10.5 | Motor Phase Current (Amperes) -- |

| Overcurrent protection | Overcurrent protection Yes | Overcurrent protection Yes | Overcurrent protection Yes |

| Amperometric protection | Amperometric protection Yes | Amperometric protection Yes | Amperometric protection Yes |

| Short circuit protection | Short circuit protection Yes | Short circuit protection Yes | Short circuit protection Yes |

| Dry running protection | Dry running protection Yes | Dry running protection Yes | Dry running protection Yes |

| Height (cm) | Height (cm) 28.2 | Height (cm) 23.5 | Height (cm) 28.2 |

| Width (cm) | Width (cm) 23.7 | Width (cm) 27.9 | Width (cm) 23.7 |

| Depth (cm) | Depth (cm) 18.4 | Depth (cm) 24.1 | Depth (cm) 18.4 |

| Weight (Kg) | Weight (Kg) -- | Weight (Kg) -- | Weight (Kg) -- |

| Warranty (years) | Warranty (years) 2 | Warranty (years) 2 | Warranty (years) 2 |

| Motor phase frequency (Hz) | Motor phase frequency (Hz) 50, 60 | Motor phase frequency (Hz) 50, 60 | Motor phase frequency (Hz) 50, 60 |